AKB-11 (6,000rpm) / AKB-13 (6,000rpm)

Horizontal Machining Centers

FEATURES

- 6000 RPM geared spindle with 37(S3 25%)/22kW (50/30 HP) motor and 1158 Nm (854 ft.lbs) high torque.

- Column traverse design provides best accessibility and chip & coolant disposal.

- No boring spindle (W axis).

- Long spindle nose design.

- High-accuracy indexing ensures standard rotary milling.

- Powerful heavy-duty cutting is capable by a high-torque 2-steps geared head.

- Standard Big-Plus dual contact system.

US Standard Specifications

| Unit | AKB-11 (6,000 rpm) | AKB-13 (6,000 rpm) | ||

|---|---|---|---|---|

| Dimensions | Machine dimensions | Inch (mm) |  |

|

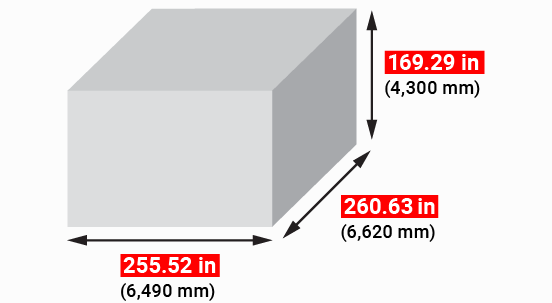

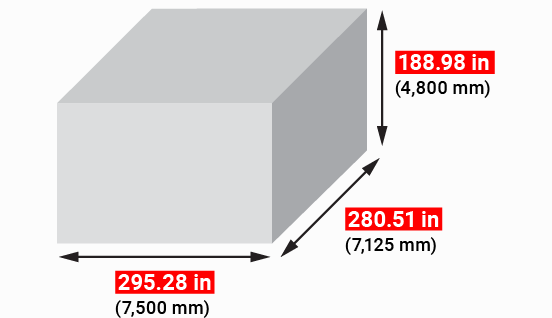

| Machine height | Inch (mm) | 169.29 (4,300) | 188.98 (4,800) | |

| Floor space (Not incl. options) | Inch (mm) | 255.52 x 260.63 (6,490 x 6,620) | 295.28 x 280.51 (7,500 x 7,125) | |

| Machine weight (incl. NC unit) | lbs (kg) | 55,000 (25,000) | 72,600 (33,000) | |

| Stroke | X axis travel (table longitudinal) | Inch (mm) | 78.74 (2,000) | 118.11 (3,000) |

| Y axis travel (spindle head vertical) | Inch (mm) | 59.06 (1,500) | 78.74 (2,000) | |

| Z axis travel (column cross) | Inch (mm) | 59.06 (1,500) | 62.99 (1,600) | |

| W axis travel (boring spindle axial) | Inch (mm) | N/A | N/A | |

| Distance from table top to spindle center | Inch (mm) | 0~59.06 (0~1,500) | 0~78.74 (0~2,000) | |

| Distance from table center to spindle nose | Inch (mm) | 17.72~76.77 (450~1,950) | 25.59~88.58 (650~2,250) | |

| Table | Table work space | Inch (mm) | 55.12 x 62.99 (1,400 x 1,600) | 70.87 x 78.74 (1,800 x 2,000) |

| Table maximum loading capacity | lbs (kg) | 14,300 (6,500) | 26,400 (12,000) | |

| Table top profile | Inch (mm) | 0.87 (22) x 7 T-slots | 0.87 (22) x 7 T-slots | |

| Table auto. Indexing | Degree | 0.001 (every 90 degree index by locator pin) | 0.001 (every 90 degree index by locator pin) | |

| Spindle Head | Spindle diameter | Inch (mm) | 5.12 (130) ***Spindle top diameter | 5.12 (130) ***Spindle top diameter |

| Spindle speed | rpm | 10~6,000 | 10~6,000 | |

| Spindle Torque (30min / Continuous) | ft.lbs (Nm) | [S3 25% / 30min / Cont.] 854 / 692 / 508 (1,158 / 939 / 689) | [S3 25% / 30min / Cont.] 854 / 692 / 508 (1,158 / 939 / 689) | |

| Spindle speed change range | step | 2 | 2 | |

| Spindle taper | 7/24 Taper No. 50 (BIG-PLUS dual contact spindle system) | 7/24 Taper No. 50 (BIG-PLUS dual contact spindle system) | ||

| Feed | Rapid traverse (X, Y, Z axes) | inch/min (m/min) | 472.44 (12) | 393.70 (10) |

| (W axis) | inch/min (m/min) | N/A | N/A | |

| Feedrate (X, Y, Z axes | inch/min (m/min) | 0.04~236.22 (1~6,000) | 0.04~157.48 (1~4,000) | |

| (W axis) | inch/min (m/min) | N/A | N/A | |

| Table revolution | rpm | 2.0 | 1.4 | |

| Automatic Tool Changer (ATC) | Tool shank | MAS CAT51 | MAS CAT50 | |

| Pull stud | MAS P50T-1 (45 degree) | MAS P50T-1 (45 degree) | ||

| Tool storage capacity | pc | 40 | 60 | |

| Max. tool diameter [vacant adjacent pots] | Inch (mm) | 4.92 (125) [9.45 (240)] | 4.92 (125) [9.45 (240)] | |

| Max. tool length) | Inch (mm) | 23.62 (600) | 23.62 (600) | |

| Max. tool weight | lbs (kg) | 55 (25) | 55 (25) | |

| Tool selection | Fixed tool pot, shortcut magazine rotation |

Fixed tool pot, shortcut magazine rotation |

||

| Motors | Spindle motor (30min/Continuous) | HP (kW) | 50/30 (37/22) ***S3 25% / Continuous | 50/30 (37/22) ***S3 25% / Continuous |

| Feed motor (X axis) | HP (kW) | 8.0 (6.0) | 8.0 (6.0) | |

| (Y axis) | HP (kW) | 4.0 (3.0) | 4.0 (3.0) | |

| (Z axis) | HP (kW) | 8.0 (6.0) | 8.0 (6.0) | |

| (W axis) | HP (kW) | N/A | N/A | |

| (B axis) | HP (kW) | 4.0 (3.0) | 4.0 (3.0) | |

| Voltage | Power capacity (Not incl. options) | kVA | 63 | 64 |

| Air pressure source pressure | MPa | 0.5 | 0.5 | |

| Air pressure source flow (Not incl. options) | NL/min (atm) | 400 | 400 |