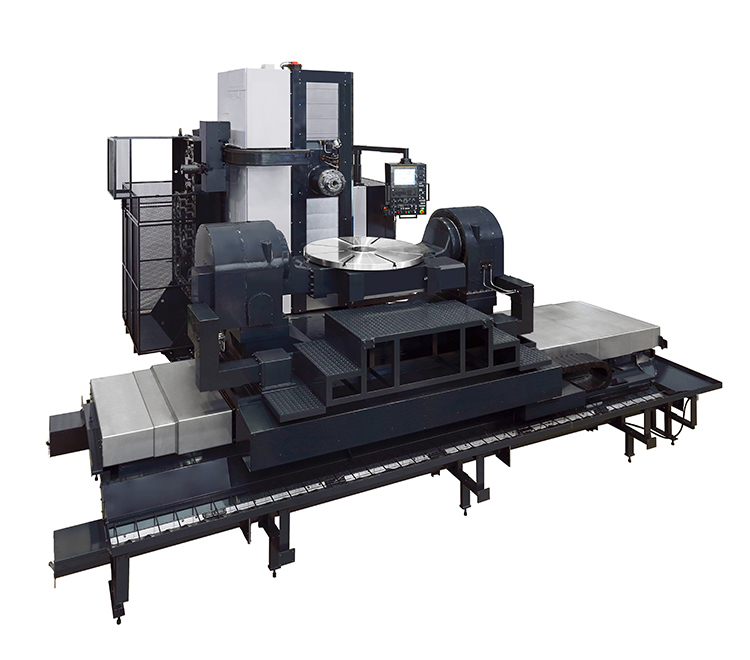

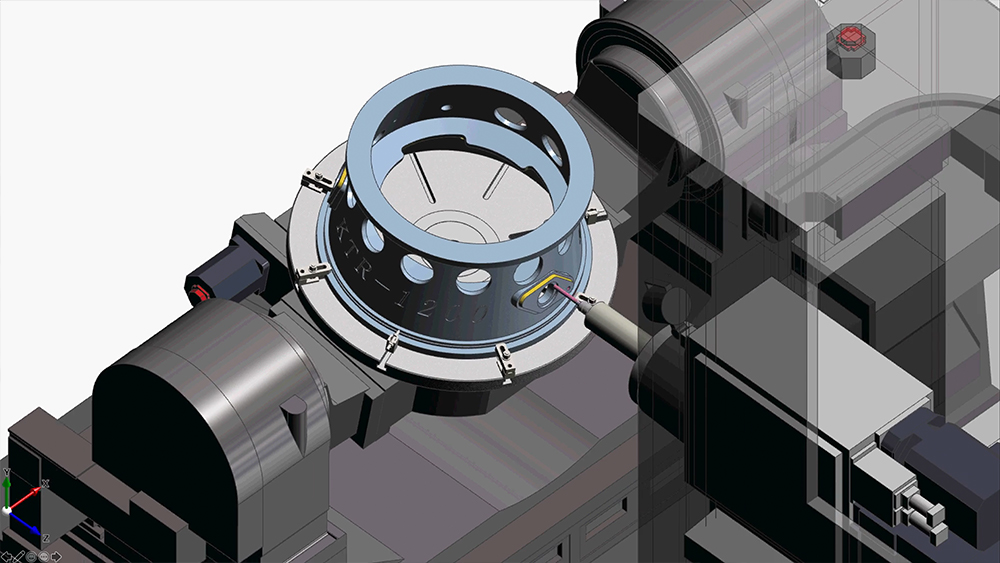

KTR-1200

6 Axis Machining Center

US Standard Specifications

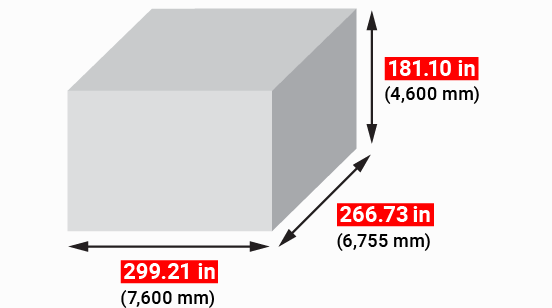

| Unit | KTR-1200 | ||

|---|---|---|---|

| Dimensions | Machine dimensions | Inch (mm) |  |

| Machine height | Inch (mm) | 181.10 (4,600) | |

| Floor space (Not incl. options) | Inch (mm) | 299.21 x 266.73 (7,600 x 6,755) | |

| Machine weight (incl. NC unit) | lbs (kg) | 88,185 (40,000) |

“ONE SET UP”

6 Axis Machining Center KTR-1200

Accessibility to Prevent Interference with the Work

- Built-in Rotary Trunnion Table

- Combination of Boring Spindle and Tilt Table increases flexibility and reduces interference

- The Boring Spindle adds rigidity with the ability to machine deep within the part without extended cutting tools

“ONE SET UP” Reduces Total Processing Time

- Can be machined with “ONE SET UP" by Rotary Trunnion Table

- Significantly reduced machining time by eliminating the need for multiple setup changes

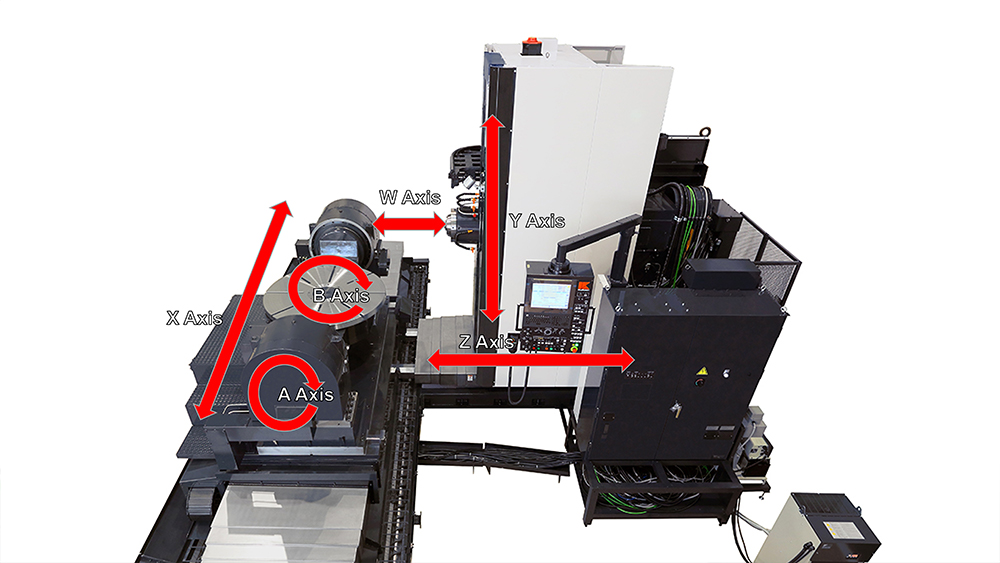

- Simultaneous 5-axis machining incorporating table rotation (B axis) and table tilt (A axis) is possible